Every year dry cleaners across the globe loose anything between USD 500-2000 by failing to track the garments. Sometimes the garments go missing while in transit between various stores to the workshop or while delivering back to customers doorstep, and sometimes due to employee pilferage. It is indeed a very tedious task to track every single garment manually and also most of the dry cleaners do not do it due to lack of knowledge of how to do it.

If you are a dry cleaner and facing the same problem then a software solution can help you reduce this waste and minimize your loss. You can choose an appropriate software solution specifically made for the dry cleaning business. With the use of the bar code technology for dry cleaners, you can create barcoded tags and scan the garments at every touch point when its location is changed.

Moving on to the next level is reconciling the stock of garments at your store. Any advanced software can help you in this cause. Following is an illustration around how can you reconcile stock in your dry cleaning business using Quick Dry Cleaning Software.

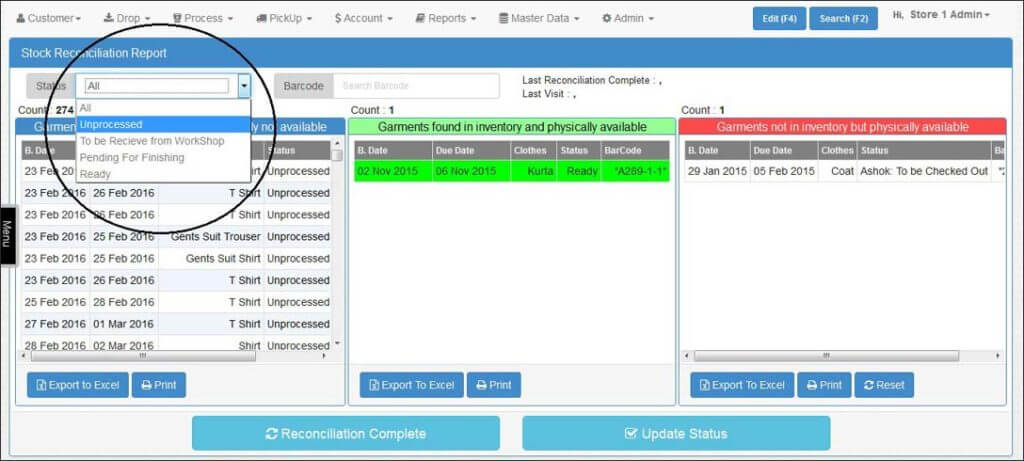

The first step is to select the status (s) of the garments you want to consider while reconciling the stock.

The screen is divided amongst 3 data sections. The left most section contains the list of all the garments that are available in the store.

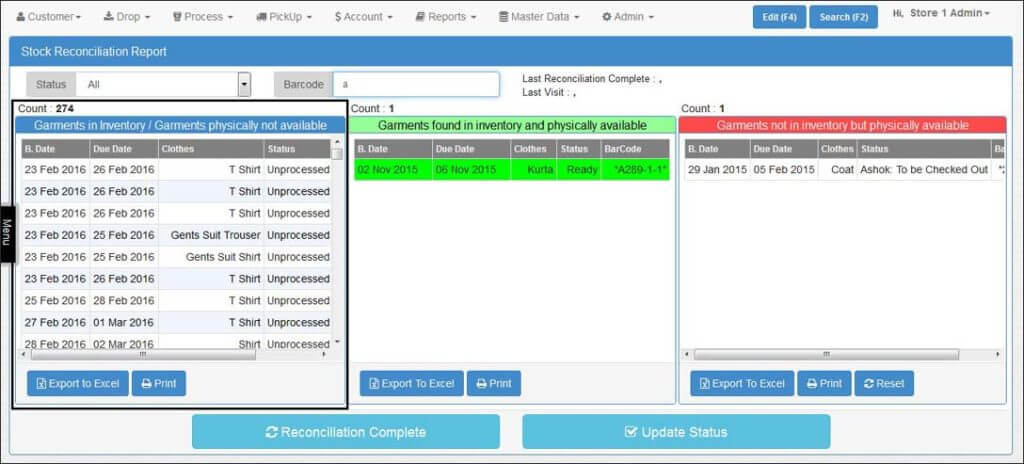

Now you are ready, to begin with, the reconciliation process. Pick up a garment and scan the bar code printed on the tag. The system will move the garment to the second or third data section based on the information stored in the software.

- Garments which are physically available and also the status is correct will be moved to the second data section (the one which is in the middle of the screen).

- Garments which are physically available but either they are not available in the system or are in the incorrect status are moved to the third data section (available on the right portion of the screen).

Continue this process till you scan all the available garments in the store. Ideally, all the garments should move from first data section to the second one. This declares that you physical data are in complete accordance with the data in the software. The presence of the garment codes in the third data section tells that there is some discrepancy, either by negligence or intentional, that needs to be investigated upon.

This process will help you to track the garments and hence be in control of your business. You can minimize the loss of the garments, set an example for your employees and make it mandatory for them to adhere to all the processes that need to be followed to ensure smooth operation of your business.